-

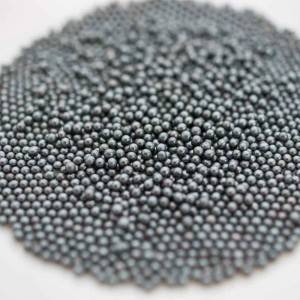

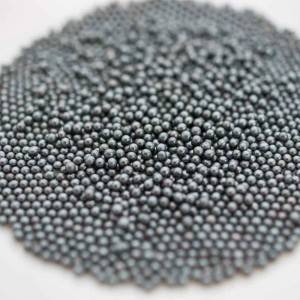

Hāpai ʻia ʻo Angular Steel Grit

Hana ʻia ʻo Bearing Angular Steel Grit me nā papa Bearing haʻihaʻi. ʻO ke kila amo ka Cr, Mo nā mea ʻokoʻa, he kūpaʻa maikaʻi i loko o ka hale. kiʻekiʻe-carbon kila grit a haʻahaʻa carbin

-

FerroSilicon

ʻO Ferrosilicon kahi ʻano ferroalloy i haku ʻia e ka hoʻemi ʻana o ka silica a i ʻole ke one me ka coke i mua o ka hao.ʻO nā kumu hao maʻamau, ʻo ia ka hao a i ʻole ka millscale.ʻO nā ferrosilicons me ka ʻike silika a hiki i ka 15% i hana ʻia i loko o nā umu ahi i hoʻopaʻa ʻia me nā pōhaku lepo.

-

Hoolei kila kila

ʻO ka pana kila kila ke ʻano media i lilo i mea kaulana.Hana ʻia kēia mau huahana me ke kila kila, akā naʻe, hana ʻia me ke kila kila.Loaʻa iā ia kahi kiʻekiʻe o ka nickel a me ka chromium.A he mau medias maikaʻi e noʻonoʻo i ka wā hiki ʻole ke hoʻohaumia ʻia ka ferrous o ka mea hana

-

Carburizers

ʻO Carburizer, i kapa ʻia ʻo carburizing agent a i ʻole carburant, he mea hoʻohui i ka hana kila a i ʻole ka hoʻolei ʻana e hoʻonui i ka ʻike kalapona.Hoʻohana ʻia nā Carburizers no ka hoʻomaʻemaʻe kila Carburizers a me ka hao Carburizers, a me nā mea hoʻohui ʻē aʻe i Carburizers, e like me nā mea hoʻohui pad brake, e like me friction material.

-

Silika Manganese Alloy

ʻO ka silikoni manganese alloy (SiMn) i haku ʻia me ke silika, manganese, hao, liʻiliʻi kalapona a me kekahi mau mea ʻē aʻe.Nā hopena o ka hoʻohui ʻana o ka silicomanganese i ke kila: He koʻikoʻi ko ka silicon a me ka manganese i nā waiwai o ke kila.

-

Barium-Silikona(BaSi)

ʻO Ferro silicon barium inoculant kahi ʻano FeSi-based alloy i loaʻa kekahi nui o ka barium a me ka calcium, hiki iā ia ke hōʻemi nui i ke ʻano anuanu, e hoʻohua ai i ke koena liʻiliʻi.No laila, ʻoi aku ka maikaʻi o Ferro silicon barium inoculant ma mua o ka inoculant i loaʻa wale i ka calcium, ma ad

-

Nodulizer(ReMgSiFe)

ʻO ka Nodulizer kahi mea hoʻohui i hiki ke hoʻoikaika i ka hana ʻana o ka graphite spheroidal mai nā ʻāpana graphite i nā kaʻina hana.Hiki iā ia ke hoʻoulu i nā graphites spheroidal a hoʻonui i ka helu o nā graphites spheroidal i mea e hoʻomaikaʻi ai ko lākou mau pono mechanical.ʻO ka hopena, ka ductility a me ka paʻakikī

-

Strontium-Silicon(SrSi)

ʻO ka Ferro silicon strontium nucleating agent kahi ʻano FeSi-based alloy i loaʻa i kekahi nui o ka barium a me ka calcium, hiki iā ia ke hōʻemi i ke ʻano anuanu, e hoʻohua ana i ke koena liʻiliʻi.No laila, ʻoi aku ka maikaʻi o Ferro silicon barium inoculant ma mua o ka inoculant i loaʻa wale ka calc

-

Kalsium-Silikona(CaSi)

Hoʻokumu ʻia ʻo Silicon Calcium Deoxidizer i nā mea o ke silika, calcium a me ka hao, he mea hoʻohui deoxidizer kūpono, desulfurization agent.Hoʻohana nui ʻia ia i ke kila kila kiʻekiʻe, ke kila kalapona haʻahaʻa, ka hana ʻana i ke kila kila a me ka nickel base alloy, titanium alloy a me nā mea hana ʻē aʻe kūikawā.

-

Magnesium-Silikona (MgSi)

ʻO Ferro silicon magnesium Nodulizer ka hoʻoheheʻe ʻana i ka alloy i haku ʻia me ka honua laʻa, ka magnesium, ke silika a me ka calcium.ʻO Ferro silicon magnesium nodulizer kahi nodulizer maikaʻi loa me ka hopena ikaika o ka deoxidation a me ka desulfurization.ʻO Ferrosilicon, Ce+La mish metala a i ʻole ka honua ferrosilicon a me ka magnesium

-

FeroManganese

ʻO Ferromanganese kahi ʻano ferroalloy i haku ʻia me ka hao a me ka manganese. ua hana ʻia ma ka hoʻomehana ʻana i ka hui ʻana o nā oxides MnO2 a me Fe2O3, me ke kalapona, maʻamau e like me ka lanahu a me ka coke, i loko o ka umu ahi a i ʻole ka ʻōnaehana ʻano umu ahi. kapa ʻia he umu ahi i hoʻopaʻa ʻia.

-

FerroChrome

ʻO Ferrochrome (FeCr) kahi huila o ka chromium a me ka hao i loaʻa ma waena o 50% a me 70% chromium. Ma luna o 80% o ka ferrochrome o ka honua i hoʻohana ʻia i ka hana ʻana i ke kila kila.E like me ka maʻiʻo kalapona, hiki ke mahele ʻia i: High carbon ferrochrome/HCFeCr(C:4% -8%), Medium carbon ferrochrome/MCFeCr(C:1% -4%), Low carbon ferrochrome/LCFeCr(C:0.25 % -0.5%), Micro carbon ferrochrome/MCFeCr:(C:0.03-0.15%). Kina no ka hoʻonui ʻana i ka nui o ka hana ferrochrome honua.

-

ʻO Ferro Molybdenum

ʻO ka Ferromolybdenum he ferroalloy i haku ʻia me ka molybdenum a me ka hao, ka mea maʻamau i loko o ka molybdenum 50 ~ 60%, hoʻohana ʻia ma ke ʻano he mea hoʻohui i ka hana kila. aniani maikai

-

Puhi Uea Oki Kuhilihao

ʻO kā mākou mea kūikawā kūikawā, hana ʻia ʻo SUS200, 300, 400 moʻo uea kila kila i ʻoki ʻia i nā ʻāpana.Ke hoʻohana ʻia nei ka pana uea ʻoki kila kila ma ka hoʻonui nui ʻana o nā noi koʻikoʻi kahi e hoʻohaumia ai ka ferrous i ka puhi ʻana i ke kila kila, titanium.

-

Paʻa kila kuhili ʻole

ʻO ke kila kila kila Forged i hana ʻia me SUS200, 300, 400 series stainless steel wire a me ka lepo i loko o nā pōpō o nā pōʻai like ʻole.

-

Kiekie Carbon Poe Steel Shot

Kiʻekiʻe kalapona kila pana, i hanaia mai loko mai o kūikawā kila, paakiki a me ka huhū, loaʻa i ka maʻiʻo i loko o carbon oi aku mamua o 0.85%.ma ka atomization kaʻina hana, spherical particles i hooheheeia steel.Fengerda strictly mana i kela loulou o ka hana, oi aku ka mana o ka deoxidation a me decarboniza

-

Pana kila Poe Kabone Haahaa

Loaʻa ka liʻiliʻi o ke kalapona kalapona, ka phosphorus a me ka sulfur ma mua o ke kila kalapona kiʻekiʻe.No laila, ʻoi aku ka maʻalahi o ka ʻōnaehana micro kūloko o nā kiʻi kalapona haʻahaʻa.ʻOi aku ka palupalu o nā kiʻi kila carbon haʻahaʻa i hoʻohālikelike ʻia me nā kiʻi kila carbon kiʻekiʻe.

-

ʻO ka pana alumini/ʻoki ʻoki uea pana

Loaʻa ka pahu uea ʻoki ʻoki alumini (Aluminum Shot) i nā māka alumini hui ʻia (4043, 5053) a me nā māka hoʻohui e like me ke ʻano 5356. ʻO kā mākou mau māka hui ʻia e hāʻawi i ka waena B waena (Ma kahi o 40) ʻO ka paʻakikī ʻo Rockwell aʻo ke ʻano 5356 e hua mai Rockwell kiʻekiʻe. B paakiki ma ka laula 50 a 70.

-

ʻO ka pana keleawe ʻulaʻula/ʻoki keleawe pana uea

1. Wehe i ka uila a hiki i ka 0.20″ mai nā mea hoʻoheheʻe make me ka ʻole e hōʻino i ka ʻili

E hoemi ana i na mea pahū

Wehe i ka pena a me nā mea uhi ʻē aʻe me ka ʻole e hōʻino i ka ʻili o ka ʻāpana

Waiho ʻia ke kiʻi ʻoniʻoni zinc ma luna o nā ʻāpana kila i ka wā o ka pōʻai e hāʻawi ana i ka pale ʻōpala no ka wā pōkole -

Pana uea Zinc/Kuhi uwea ʻoki Zinc

Hāʻawi mākou i kahi ʻano qualitative o Zinc Cut Wire Shots.Loaʻa i nā kumukūʻai kūpono, hoʻemi kā mākou huahana i ka ʻaʻahu a me ka waimaka ma nā mea pahū.ʻOi aku ka palupalu o kēia mau kiʻi uea ʻoki Zinc ma mua o ka uea ʻoki kila kila a i ʻole nā huahana hoʻolei.Loaʻa ka pana uea ʻoki Zinc i nā nui like ʻole.

-

Puhi kila wili

Hoʻokumu ʻia ka Alloy grinding steel shot ma ke kiʻekiʻe-carbon pana kila, haʻahaʻa-carbon kila pana, a me ka haʻahaʻa vanadium pana kila, e noʻonoʻo ana i ka nāwaliwali make o nā huahana i luna: ea lua, māwae, ʻokoʻa paʻakikī, hoʻomohala i nā huahana hou ma o ka huli ʻana i ka ʻenehana forging, hiki iā ia ke koho i nā mea like ʻole

-

Pōpopo kila

Hana ʻia ka pōʻaiapili kila me ke kila poepoe e like me ka mea maka, ka mea i hana kino ʻia e ka ʻenehana ʻōwili a me ka forging hou a laila hana ʻia e ka ʻenehana lapaʻau wela kūikawā.

Ma hope o nā makahiki o ka hōʻiliʻili ʻana o ka ʻike a me nā hoʻāʻo hou ʻana, -

Oki Wire Shot/Uea Hou

Hana ʻia ʻo Cut Wire Shot mai ka uea kiʻekiʻe i ʻoki ʻia i ka lōʻihi e like me kona anawaena.ʻO ka uea i hoʻohana ʻia no ka hana ʻana i ka ʻoki Wire Shot hiki ke hana ʻia me Carbon Steel, Stainless Steel, Aluminum, Zinc, Nickel Alloy, Copper a i ʻole nā mea metala ʻē aʻe.Aia nō nā kihi ʻoi o ka ʻoki ʻana

-

ʻOki Wire Shot/Hoʻohana Uea

ʻO ke kiʻi uea ʻoki kila recycled he ʻano huahana ia e hoʻohana ai i nā mea hana hou, ʻoi aku ka haʻahaʻa o kāna kumu kūʻai, a paʻakikī hoʻi e hana i nā huahana kiʻekiʻe, hiki ke hoʻohana ʻia kēia ʻano huahana no ka hoʻomaʻemaʻe ʻana i ka ʻili. nā wahi.No nā mea kūʻai i loaʻa ʻole kahi kūikawā

-

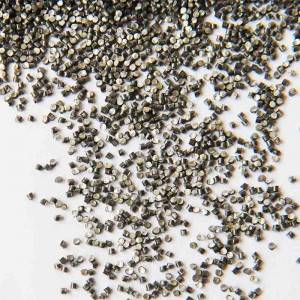

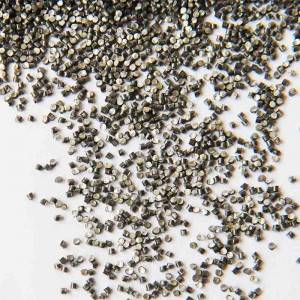

Kiekie Carbon Angular Steel Grit

Hana ʻia ke kalapona kiʻekiʻe angular steel grit mai ke kiʻekiʻe carbon steel pana.ʻO nā kiʻi kila i ʻoki ʻia a hiki i ke ʻano grit granular a ma hope i hoʻohālikelike ʻia i ʻekolu paʻakikī like ʻole (GH, GL a me GP) e hoʻokō i nā noi like ʻole.Hoʻohana nui ʻia ke kila kalapona kiʻekiʻe ma ke ʻano he media no ka descali

-

ʻO ke kila ʻāʻī kaona haʻahaʻa

Hana ʻia ka liʻiliʻi carbon angular steel grit mai ke kila kalapona haʻahaʻa

pana. ʻO nā kiʻi kila i ʻoki ʻia a hiki i ka puʻupuʻu.

- Kelepona

- 0086-632-5985228

- leka uila

- info@fengerda.com