Cut Wire Shot/New Wire

Model/Size:Φ0.2mm-2.8mm

Product Detail:

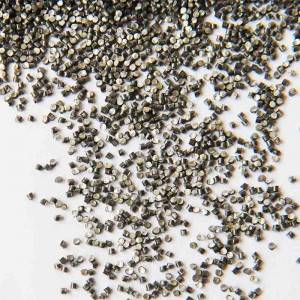

Cut Wire Shot is manufactured from high quality wire which is cut to a length about equal to its diameter. The wire used to produce Cut Wire Shot can be made of Carbon Steel, Stainless Steel, Aluminum, Zinc, Nickel Alloy, Copper or other metal alloys. It still has the sharp corners from the cutting operation. As-cut wire shot is an effective cleaning abrasive but it isn't suitable for shot peening applications since the sharp edges are potentially damaging to fatigue life.

The hardness of new wire can reach 50-60HRC, even more than 60HRC, and the life is longer than the old wire.And the color of new cutting wire shot is more bright, suitable for large workpiece which has requirements on the surface of casting.

Key Specifications:

|

PROJECT |

SPECIFICATION |

TEST METHOD |

|||

|

CHEMICAL COMPOSITION |

|

0.45-0.75% |

P |

≤0.04% |

ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

Si |

0.10-0.30% |

Cr |

/ |

||

|

Mn |

0.40-1.5% |

Mo |

/ |

||

|

S |

≤0.04% |

Ni |

/ |

||

|

MICROTRUCTURE |

Deformed pearlite,carbide network≤class 3 |

GB/T 19816.5-2005 |

|||

|

Density |

7.8g/cm³ |

GB/T 19816.4-2005 |

|||

|

EXTERNALFORM |

Cylindrical shape,flat shape≤10%,trimming and burrs ≤18% |

Visual |

|||

|

HARDNESS |

HRC40-60 |

GB/T 19816.3-2005 |

|||

The Advantages of Steel Cut Wire Shot

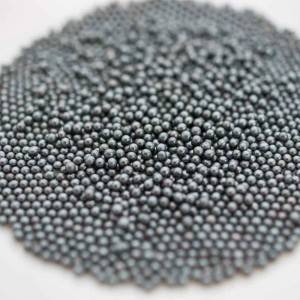

Highest Durability

Due to its wrought internal structure with virtually no internal defects (cracks, porosity and shrinkage), the durability of Cut Wire Shot is significantly greater than other commonly used metallic media.

Highest Consistency

Cut Wire Shot media has the highest consistency from particle to particle in size, shape, hardness and density.

Highest Resistance to Fracture

Cut Wire Shot media tends to wear down and become smaller in size rather than fracturing into sharp-edged broken particles, which may cause surface damage to the part.

Lower Dust Generation

Cut Wire Shot is more durable and resistant to fracture, resulting in a lower dust generation rate.

Lower Surface Contamination

Cut Wire Shot does not have an Iron Oxide coating or leave Iron Oxide residue—parts are cleaner and brighter.