Popular Design for Sandblasting Grit - Stainless Steel Cut Wire Shot – Feng Erda

Popular Design for Sandblasting Grit - Stainless Steel Cut Wire Shot – Feng Erda Detail:

Model/Size:0.2-2.5mm

Product Detail:

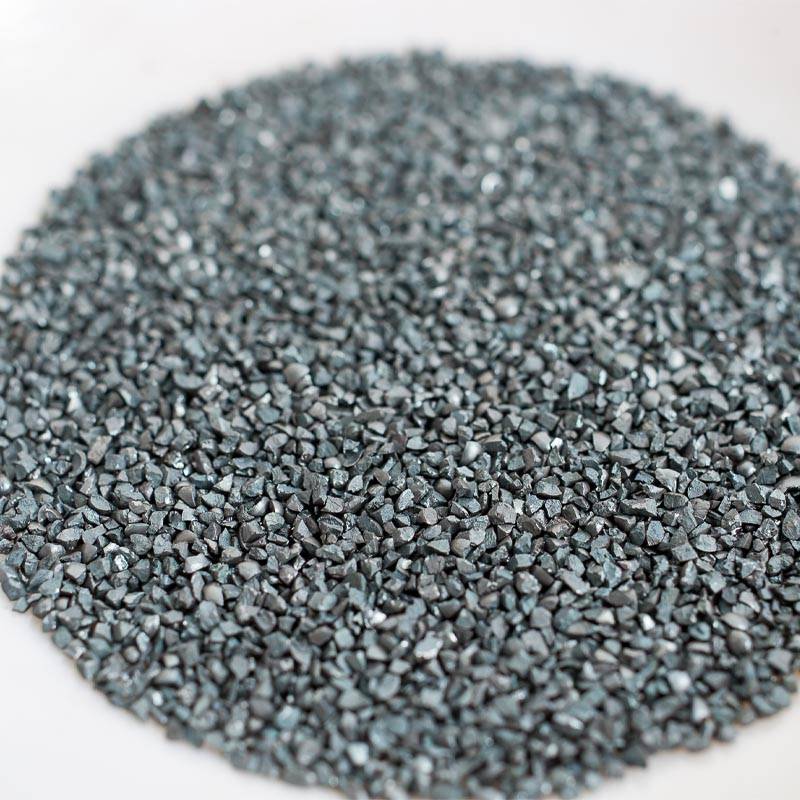

Stainless steel cut wire shot is our particular specialty.It is made of SUS200, 300, 400 series stainless steel wire cut into segments. Stainless steel cut wire shot is being used in an increasing number of important applications where ferrous contamination in blasting stainless steel, titanium, aluminum, or other non-ferrous work objects could be harmful. It is also used in peening these metals (stainless steel, titanium, brass or aluminum) in work objects that are subject to stress corrosion cracking.

Key Specifications:

|

PROJECT |

SPECIFICATION |

TEST METHOD |

|||

|

CHEMICAL COMPOSITION |

|

≤0.8% |

P |

0.045% |

ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

Si |

1.00% |

Cr |

18.0-20.0% |

||

|

Mn |

≤2.0% |

Ni |

8.0-10.0% |

||

|

S |

0.030% |

Mo |

/ |

||

|

MICROTRUCTURE |

Deforned Austenite |

GB/T 19816.5-2005 |

|||

|

Density |

7.8g/cm³ |

GB/T 19816.4-2005 |

|||

|

EXTERNALFORM |

Glossy rustless surface,cylindrical shape |

Visual |

|||

|

HARDNESS |

HV:240-600(HRC20.3-55.2) |

GB/T 19816.3-2005 |

|||

Raw Material :

The economic case for using stainless cut wire shot in peening and blast cleaning operations is quite easy to make. Cut wire does not fracture or break down during use because it is a solid piece. As a result, you get these benefits:

①Stainless steel cut wire shot has a significantly longer useful life than cast steel shot or grit and carbon cut wire shot

②Dust generation is significantly lower – blasting operations are much cleaner

③Stainless steel cut wire shot produces excellent results because of its uniformity and strength

④It will make you a “Greener” organization because disposal of spent media will be significantly reduced. (You won’t need as much shot, inventory requirements will be lower, and inbound freight will cost less.)

⑤You will NOT introduce ferrous contamination to non-ferrous castings or work objects as occurs with the use of cast steel or carbon cut wire shot

Applications:

300 SERIES

Applications: Prevents ferrous contamination when blasting or peening stainless steel, titanium, aluminum, or other non-ferrous work objects.

Specs: Available in conditioned form with certification to meet MILS 13165C, SAE J441, and aerospace specification AMS 2431/4. Stainless Steel Cut Wire Shot has a Rockwell C hardness of 50 – 58 HRC

400 SERIES

Applications: For preparing aluminum for paint removal and on aluminum die castings for deflashing and finishing.

Specs: Prevents ferrous contamination – but softer (at HRC 30 – 35) and less expensive than 300 Series Stainless.

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great excellent command throughout all stages of generation enables us to guarantee total customer fulfillment for Popular Design for Sandblasting Grit - Stainless Steel Cut Wire Shot – Feng Erda , The product will supply to all over the world, such as: Gambia, Casablanca, Nepal, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.