One of Hottest for Grinding Steels Shot Suppliers - Low Carbon Rounded Steel Shot – Feng Erda

One of Hottest for Grinding Steels Shot Suppliers - Low Carbon Rounded Steel Shot – Feng Erda Detail:

Model/Size:S110-S930/Φ0.3mm-2.8mm

Product Detail:

Low carbon steel shots contain less carbon, phosphorus and sulfur than high carbon steel shots. Therefore, the internal micro structure of low carbon shots are much smoother. Low carbon steel shots are softer compared to high carbon steel shots too. This results in 20 – 40 % longer abrasive life time.

Key Specifications:

|

PROJECT |

SPECIFICATION |

TEST METHOD |

|||

|

CHEMICAL COMPOSITION |

C |

0.08-0.2% |

P |

≤0.05% |

ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

|

Si |

0.1-2.0% |

Cr |

/ |

|

|

|

Mn |

0.35-1.5% |

Mo |

/ |

|

|

|

S |

≤0.05% |

Ni |

/ |

|

|

MICROTRUCTURE |

Homogeneous Martensite or Bainite |

GB/T 19816.5-2005 |

|||

|

Density |

≥7.0-10³kg/m³(7.0kg/dm³) |

GB/T 19816.4-2005 |

|||

|

EXTERNALFORM |

Air hole < 10%. Conjoins. Sharp corner. Deformity Rate< 10% |

Visual |

|||

|

HARDNESS |

HV:390-530(HRC39.8-51.1) |

GB/T 19816.3-2005 |

|||

Processing Steps:

Scrap→Select&Cutting→Melting→Refine(decarbonize)→Atomizing→Drying→Scalper Screening→Spiralizing&Blowing to remove the air hole→The first quenching→Drying→Derusting→The second tempering→Cooling→Fine Screening→Packing&Warehousing

Applications:

Typical application areas: pre-treatment of steel or cast-iron surfaces before painting, descaling and rust removal, deburring.

Advantages:

① Ideal for use to provide clean, polished metal surface.

② Low carbon steel shots are used in both turbine and compressed air blasting systems. Low carbon steel shots ensure lower turbine blades wear.

③Low carbon steel shots life cycle is about 30% longer than conventional high carbon steel shots.

④ Shot blasting process produces less dust, that results in lower maintenance costs of filtration system.

Why Low Carbon?

Low carbon and high manganese steel shot have high impact absorption capacity, impacts are distributed uniformly throughout the shot.

During shot blasting operations, low carbon steel shot is peeled down into thin layers similar to the layers of onions for up to 80 percent of their life due to wear, and are only broken into small pieces due to fatigue of the material. Machine and blade erosion are also significantly reduced as they are divided into lesser and smaller parts.

High carbon steel shot particles however are broken into large and angular pieces in a short time due to the crack structure formed during production. With this feature, the machine causes high extra costs on turbine equipment and filters.

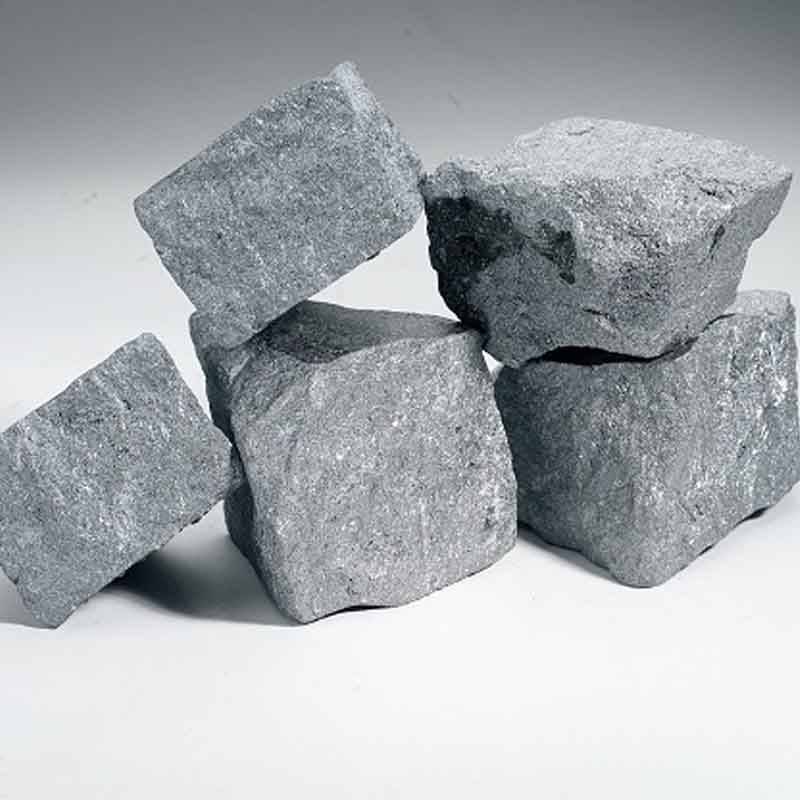

Product detail pictures:

Related Product Guide:

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for One of Hottest for Grinding Steels Shot Suppliers - Low Carbon Rounded Steel Shot – Feng Erda , The product will supply to all over the world, such as: Egypt, Luxemburg, Mexico, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we provide, effective and satisfying consultation service is supplied by our professional after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So you should make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We've been confident that we have been going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!