Wholesale Discount Hi Tech Abrasives - Bearing Angular Steel Grit – Feng Erda

Wholesale Discount Hi Tech Abrasives - Bearing Angular Steel Grit – Feng Erda Detail:

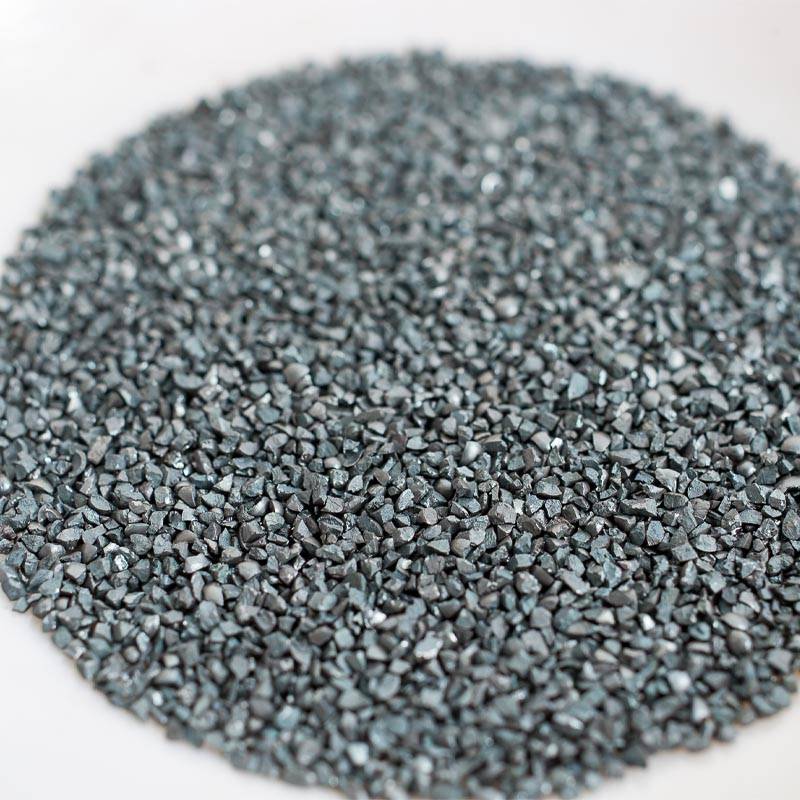

Model/Size:G12-G150 Φ0.1mm-2.8mm

Product Detail:

Bearing Angular Steel Grit is made of brokened Bearing plates.The bearing steel has Cr,Mo rare elements,it has good stability inside structure .Bearing anguler steel grit has high stable performance,high wear resistance,its working life is 2.5 times as long as high-carbon steel grit and low carbin steel grit.

Key Specifications:

|

PROJECT |

SPECIFICATION |

TEST METHOD |

|||

|

CHEMICAL COMPOSITION |

C |

0.65-1.2% |

P |

≤0.025% |

ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

|

Si |

0.15-0.6% |

Cr |

0.2-0.4% |

|

|

|

Mn |

0.45-0.85% |

Mo |

0.1-0.15% |

|

|

|

S |

≤0.025% |

Ni |

/ |

|

|

MICROTRUCTURE |

Homogeneous tampered sorbite |

GB/T 19816.5-2005 |

|||

|

Density |

≥7.4g/cm³ |

GB/T 19816.4-2005 |

|||

|

EXTERNALFORM |

Flat shape,much angular,sharp angular |

Visual |

|||

|

HARDNESS |

HV:600-700(HRC55-60) HV:700-810(HRC60-65) |

GB/T 19816.3-2005 |

|||

Advantages and Applications

① Bearing angular steel grit is stable in material, excellent in composition, and contains the rare element Cr Mo,High hardness, especially suitable for shipbuilding and pipeline and other large workpiece.

②Bearing angular steel grit production process is different, the production process does not change the composition of raw materials and characteristics.

③It is specially used to cut granite and can help customers to achieve faster-cutting efficiency and smoother cutting surface attributed to its sharp edges,uniform sizes and good wear resistance.

④Bearing angular steel grit is not easy to break, small dust, can effectively improve the working environment of sand blasting workshop,reduce the load on the dust collector environmental protection, and health.

⑤This new steel grit is made from bearing off-cut steel which maintains FORGING STATE, but not CASTING STATE. With the professional process of quenching, crushing, sieving and special heat treatments, such a grit shows angular shape with features of abrasive resistance and impact ductility. During the usage ,it is proved that the angular shape of the grit will gradually becomes arc, which is suitable for oxygenated surface descaling, surface cleaning and surface peening, so as to greatly improve the blasting efficiency and coating quality, and to reduce kinetic energy of paint, abrasive consumption and so on, as well as to prolong the life of wearing parts.

Product detail pictures:

Related Product Guide:

The organization keeps for the procedure concept "scientific administration, superior quality and effectiveness primacy, shopper supreme for Wholesale Discount Hi Tech Abrasives - Bearing Angular Steel Grit – Feng Erda , The product will supply to all over the world, such as: kazakhstan, Atlanta, Cairo, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!