Well-designed Cut Wire Shot - High Carbon Angular Steel Grit – Feng Erda

Well-designed Cut Wire Shot - High Carbon Angular Steel Grit – Feng Erda Detail:

Model/Size:G12-G150 Φ0.1mm-2.8mm

Product Detail:

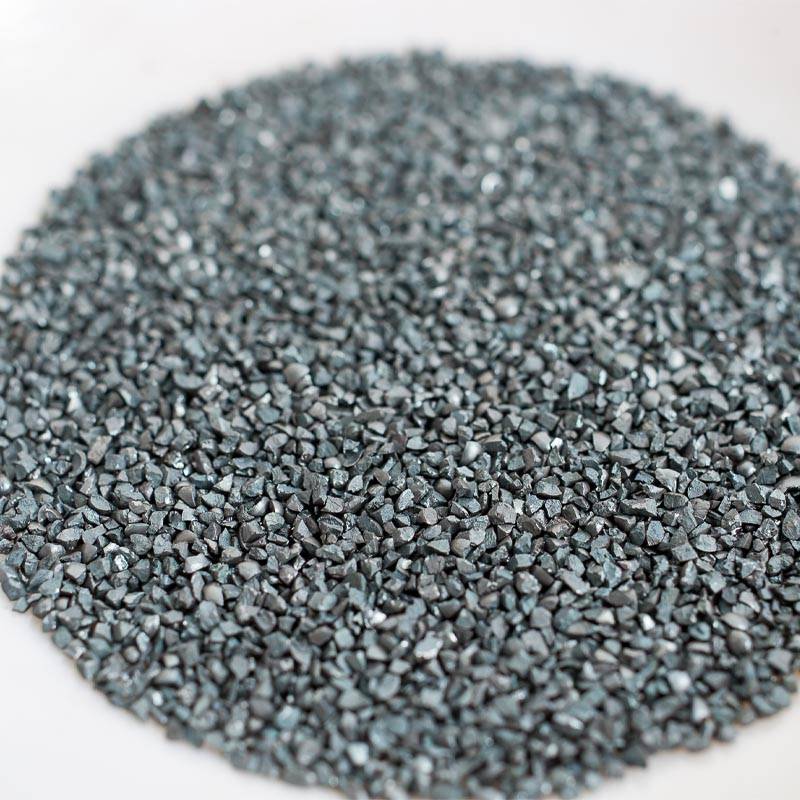

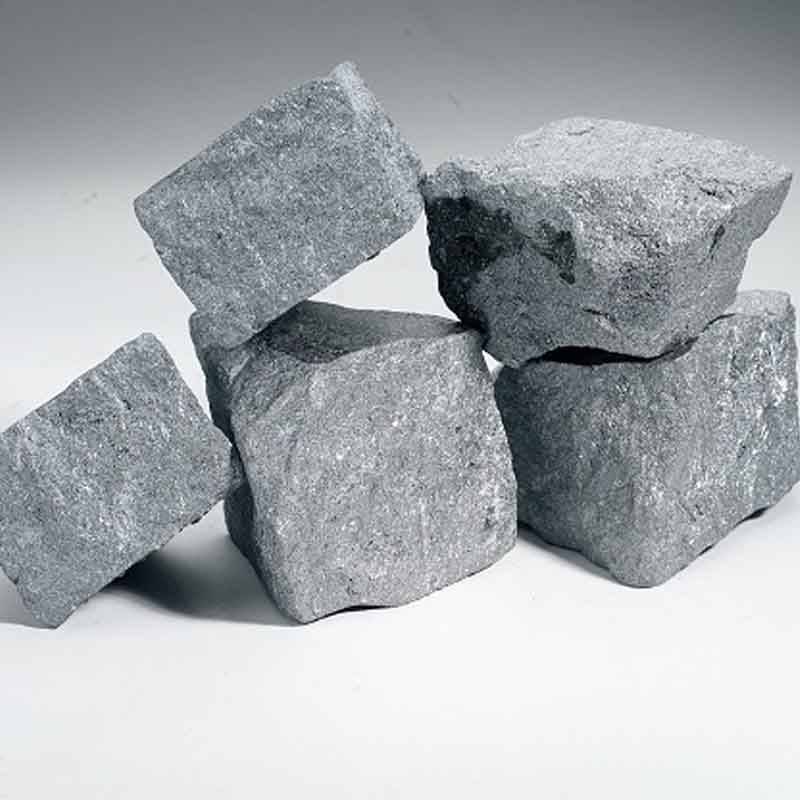

High carbon angular steel grit is manufactured from high carbon steel shot. Steel shots that are crushed to granular grit form and subsequently tempered to three different hardnesses (GH, GL and GP) to cater for different applications. High carbon steel grit is widely used as a media for de- scaling steel components prior to coating.

Key Specifications:

|

PROJECT |

SPECIFICATION |

TEST METHOD |

|||

|

CHEMICAL COMPOSITION |

|

0.8-1.2% |

P |

≤0.05% |

ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

Si |

≥0.4% |

Cr |

/ |

||

|

Mn |

0.35-1.2% |

Mo |

/ |

||

|

S |

≤0.05% |

Ni |

/ |

||

|

MICROTRUCTURE |

Homogeneous Martensite or Bainite |

GB/T 19816.5-2005 |

|||

|

Density |

≥7.0-10³kg/m³(7.0kg/dm³) |

GB/T 19816.4-2005 |

|||

|

EXTERNALFORM |

Etched or angular surface profile, Air hole < 10%. |

Visual |

|||

|

HARDNESS |

HV:390-720(HRC39.8-64) |

GB/T 19816.3-2005 |

|||

Processing Steps:

Applications:

High Carbon Steel Grit GP: Has the lowest hardness in the range of 40 to 50 HRC and is also revered to as angular shot, because the grit will get a round shape during its lifetime. It Is mainly used in wheel blast machines and it has good results in the foundry industry because it cleans faster with little increase in maintenance costs and machine parts wear. GP is used for cleaning, descaling and desanding.

High Carbon Steel Grit GL: Has a medium hardness in the range 50 to 60 HRC. It is used in wheel blast machines and blast rooms and is particularly suited to heavy descaling and surface preparation requirements. Although GL is of medium hardness, it also loses its angular shape during shot blasting.

High Carbon Steel Grit GH :The maximum hardness ranging from 60 to 64 HRC. It stays angular in the operating mix and is therefore ideally suited for surface etching requirements. GH is often used in blast rooms (compressed air shot peening equipment.) for quick cleaning and to achieve an anchor profile prior to coating.

Product detail pictures:

Related Product Guide:

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for Well-designed Cut Wire Shot - High Carbon Angular Steel Grit – Feng Erda , The product will supply to all over the world, such as: Thailand, Tunisia, Eindhoven, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.