Super Lowest Price Steel Sand - Low Carbon Angular Steel Grit – Feng Erda

Super Lowest Price Steel Sand - Low Carbon Angular Steel Grit – Feng Erda Detail:

Key Specifications:

|

PROJECT |

SPECIFICATION |

TEST METHOD |

|||

|

CHEMICAL COMPOSITION |

C |

0.08-0.2% |

P |

≤0.05% |

ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

|

Si |

0.1-2.0% |

Cr |

/ |

|

|

|

Mn |

0.35-1.5% |

Mo |

/ |

|

|

|

S |

≤0.05% |

Ni |

/ |

|

|

MICROTRUCTURE |

Homogeneous Martensite or Bainite |

GB/T 19816.5-2005 |

|||

|

Density |

≥7.0-10³kg/m³(7.0kg/dm³) |

GB/T 19816.4-2005 |

|||

|

EXTERNALFORM |

Etched or angular surface profile, Air hole < 10%. |

Visual |

|||

|

HARDNESS |

HV:390-530(HRC39.8-51.1) |

GB/T 19816.3-2005 |

|||

Processing Steps:

Scrap→Select&Cutting→Melting→Refine(decarbonize)→Atomizing→Drying→Scalper Screening→Spiralizing&Blowing to remove the air hole→The first quenching→Drying→Derusting→The second tempering→Cooling→Broken→Fine Screening→Packing&Warehousing

LOW CARBON STEEL GRANAL ADVANTAGE COST

• Performance over 20% against high carbon shots

• Less wear of machinery and equipment due to the greater absorption of energy in the impacts in the pieces

• Particles free of defects generated by thermal treatment, fractures or micro cracks

IMPROVING THE ENVIRONMENT

• Powder reduction

• Bainitic microstructure guarantees that they will not break during its useful life

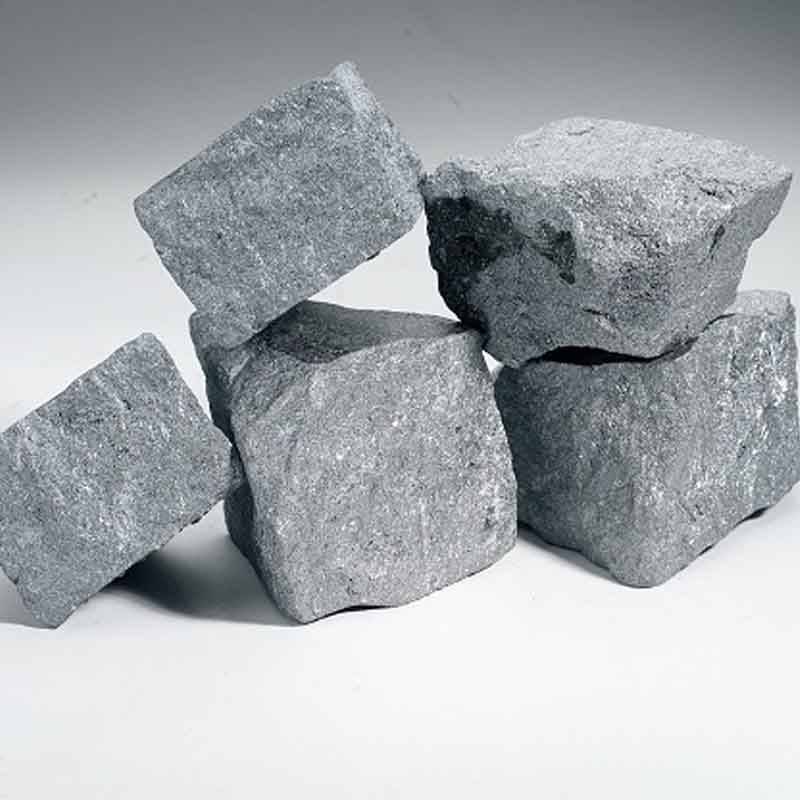

GENERAL APPEARANCE

The shape of the low carbon steel shot is similar to spherical. The minimal presence of elongated, deformed particles with pores, slag or dirt is possible.

This does not affect the performance of the shot, it can be confirmed by measuring its performance on the machine.

HARDNESS

The bainitic microstructure guarantees a high degree of hardness. 90% of the particles are between 40 – 50 Rockwell C.

The low carbon in balance with the manganese guarantees a long useful life of the particles, thus improving the cleanliness of the pieces, since with mechanical work they increase their hardness.

The energy of the shot blasting is absorbed mainly by the parts, thus reducing the wear of the machine.

CARBON GRANULATION, HIGH PERFORMANCE

The use of the low carbon steel shot has scope for machines that have turbines of 2500 to 3000 RPM and speeds of 80 M / S.

For new equipment that uses 3600 RPM turbines and speeds of 110 M / S, these are requirements to increase productivity.

Product detail pictures:

Related Product Guide:

In order to give you convenience and enlarge our business, we also have inspectors in QC Team and assure you our best service and product for Super Lowest Price Steel Sand - Low Carbon Angular Steel Grit – Feng Erda , The product will supply to all over the world, such as: Victoria, Doha, Georgia, With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our goods, make sure you contact us now. We're looking forward to hearing from you soon.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.