Rapid Delivery for Grit Blasting - Zinc shot/Zinc cut wire shot – Feng Erda

Rapid Delivery for Grit Blasting - Zinc shot/Zinc cut wire shot – Feng Erda Detail:

Model/Size:0.6-2.5mm

Product Detail:

We offer a qualitative range of Zinc Cut Wire Shots. Available at competent rates, our products reduce wear and tear on blast equipment. These Zinc cut wire shots are softer than stainless steel cut wire or cast products. Zinc cut wire shot is available in different sizes.

Zinc Cut Wire Shot is produced by cutting zinc wire into pellets, the length equal to the diameter of the wire. Zinc Cut Wire is used mainly for sand removal, deburring and deflashing of non ferrous components. Zinc Cut Wire is also available in a conditioned form which is used as a longer lasting alternative to cast zinc shot.

Deburring and deflashing of aluminium and zinc castings and die-castings. Removal of sand from sand castings. Removal of parting lines and stains from non ferrous castings. Removal of water wrinkle from aluminium die castings and providing a luster satin type finish. Zinc Cut Wire provides temporary corrosion protection to ferrous parts blasted with it. A very thin layer, up to 1.3μm thick is deposited onto the surface of the part.

Key Specifications:

|

PROJECT |

SPECIFICATION |

|||

|

CHEMICAL COMPOSITION |

Fe |

0.004% |

Cu |

0.001% |

|

Zn |

99.99% |

Cr |

/ |

|

|

Al |

0.003% |

Mo |

/ |

|

|

Cd |

0.002% |

Ni |

/ |

|

|

Hardness |

HRC35-55 or HRC45-60 |

|||

|

Density |

7.1gm/cm³ |

|||

|

EXTERNALFORM |

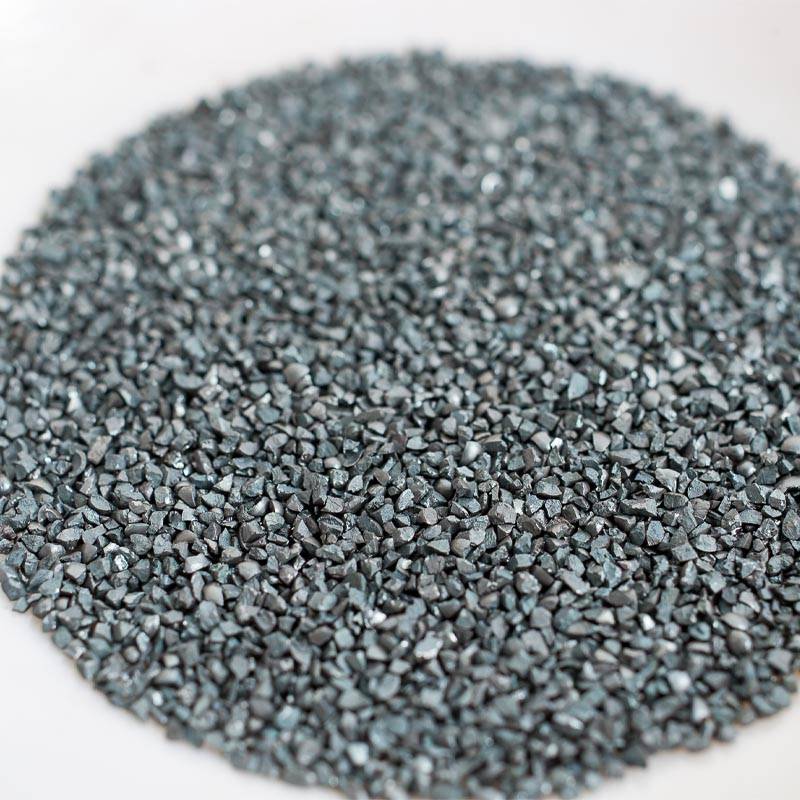

Grey colour,Cylindrical shape or Spherical shape |

|||

Applications:

Deburring and deflashing of aluminium and zinc castings and die-‐castings. Removal of sand from sand castings.

Removal of parting lines and stains fromnon ferrous castings. Removal of water wrinkle from aluminium die castings and providing a luster satin type finish.

Zinc Cut Wire provides temporary corrosion protection to ferrous parts blasted with it. A very thin layer, up to 1.3μm thick is deposited onto the surface of the part.zinc provides additional corrosion resistance.

Provide different roundness as required.

Product detail pictures:

Related Product Guide:

Sticking to the perception of "Creating products of top of the range and earning mates with people today from all over the world", we constantly put the desire of consumers in the first place for Rapid Delivery for Grit Blasting - Zinc shot/Zinc cut wire shot – Feng Erda , The product will supply to all over the world, such as: Moscow, Comoros, Gambia, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!