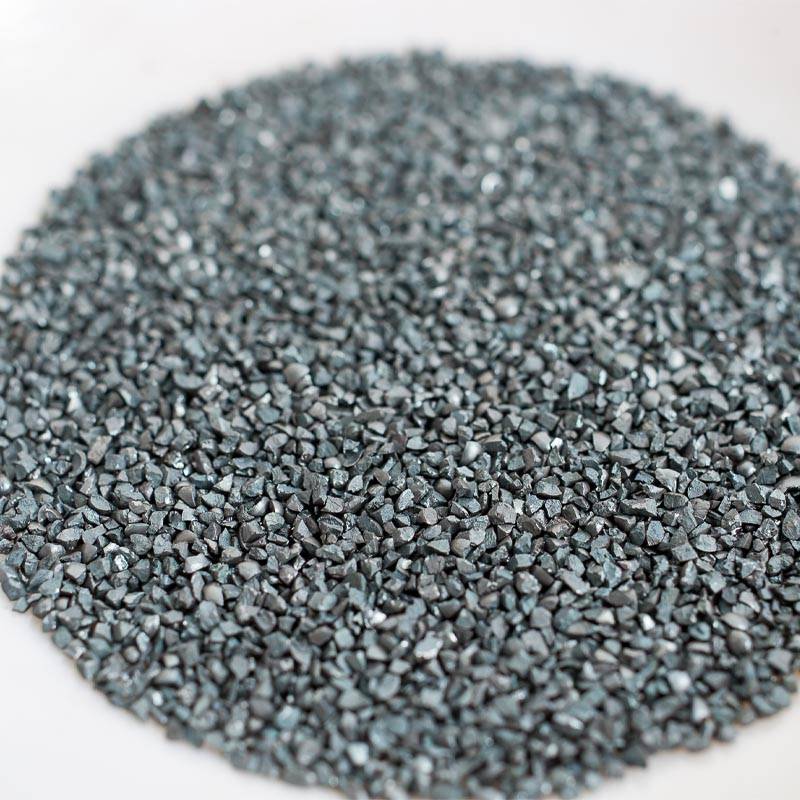

Popular Design for Sandblasting Grit - Forging steel ball – Feng Erda

Popular Design for Sandblasting Grit - Forging steel ball – Feng Erda Detail:

Model/Size:30-150mm

Product Detail:

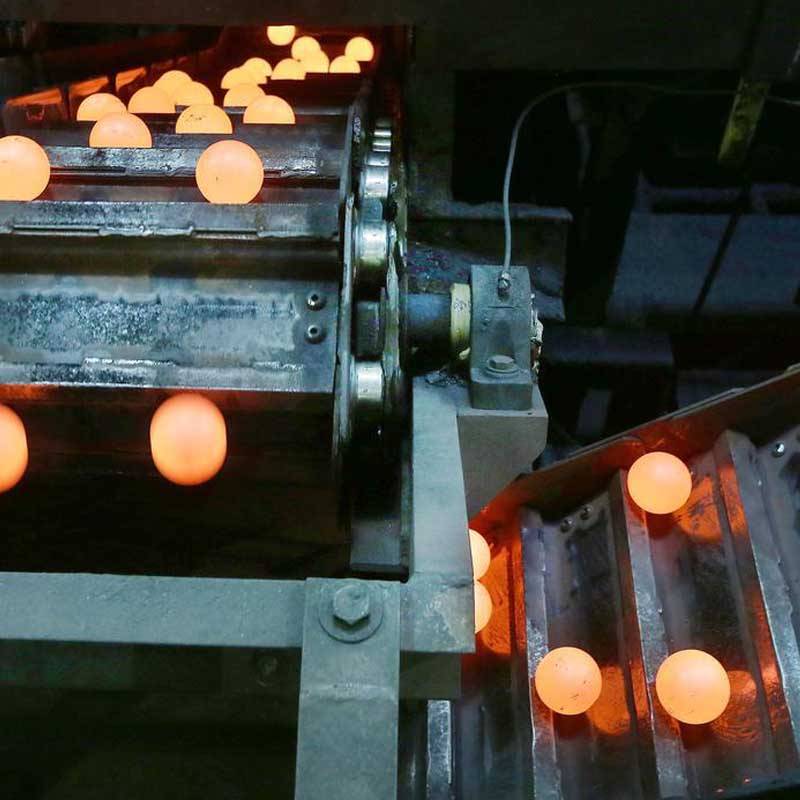

Forging steel roling ball is made of round steel as raw material, which is physically processed by new rolling and forging technology and then manufactured by special heat treatment technology.

After years of experience accumulation and repeated tests, it is concluded that the most suitable materials for forging rolled steel ball are 45#, 65Mn, 70Mn, B2 (70MnCr) and so on.Of course, some factories also have special needs, our company can customize production according to customer requirements.

Forging steel rolling ball Four advantages

High hardness Ball center HRC>46,Surface HRC56-60

Higher wear resistance The inner structure is compact and the grain is fine

High impact Impact toughness up to 12-35J/c㎡

Antifatigue The drop life of 6.5m is 20,000 times

How do we guarantee the quality of our steel balls?

01 Take high-quality billets as raw materials,and transfer the properties of steel directly to steel balls.

Steel has high strength,good comprehensive performance,corrosion resistance,wear resistance and so on.

Good material

02 Advanced supporting equipment

The supporting equipment is designed bu experts from the National Research Institute to ensure the quality of rolling and firging.

03 Unique heat treatment technology

The company implements multiple unique heat treatment processes to ensure the hardness,thoughness and wear resistance.

Rotary heat treatment

Water heat treatment

Thermal insulation heat treatment

Key Specifications:

|

Code |

C(%) |

Si(%) |

Mn(%) |

Cr(%) |

Cu(%) |

Mo(%) |

P(%) |

S(%) |

Ni(%) |

|

45# |

0.42-0.50 |

0.17-0.37 |

0.5-0.80 |

0-0.25 |

0-0.25 |

0-0.30 |

0-0.035 |

0-0.035 |

0-0.30 |

|

40Mn |

0.37-0.44 |

0.17-0.37 |

0.7-1.0 |

0-0.25 |

0-0.25 |

0-0.30 |

0-0.035 |

0-0.035 |

0-0.30 |

|

65Mn |

0.62-0.70 |

0.17-0.37 |

0.90-1.0 |

0-0.25 |

0-0.25 |

0-0.30 |

0-0.035 |

0-0.035 |

0-0.30 |

|

70Mn |

0.67-0.75 |

0.17-0.37 |

0.90-1.2 |

0-0.25 |

0-0.25 |

0-0.30 |

0-0.035 |

0-0.035 |

0-0.30 |

|

40Cr |

0.37-0.45 |

0.17-0.37 |

0.50-0.8 |

0.8-1.1 |

0-0.25 |

0-0.30 |

0-0.035 |

0-0.035 |

0-0.30 |

|

70Cr2 |

0.65-0.75 |

0.20-0.30 |

0.75-0.9 |

0.55-0.7 |

0-0.25 |

0-0.30 |

0-0.030 |

0-0.030 |

0-0.30 |

|

B-2 |

0.70-0.80 |

0.17-0.37 |

0.70-0.8 |

0.50-0.6 |

0-0.25 |

0-0.30 |

0-0.035 |

0-0.035 |

0-0.30 |

Product detail pictures:

Related Product Guide:

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for Popular Design for Sandblasting Grit - Forging steel ball – Feng Erda , The product will supply to all over the world, such as: Estonia, Greece, Colombia, Many kinds of different products are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products with us!!

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!