factory low price FeMo70 - Barium-Silicon(BaSi) – Feng Erda

factory low price FeMo70 - Barium-Silicon(BaSi) – Feng Erda Detail:

Product name: Ferro Silicon barium inoculant (Basi)

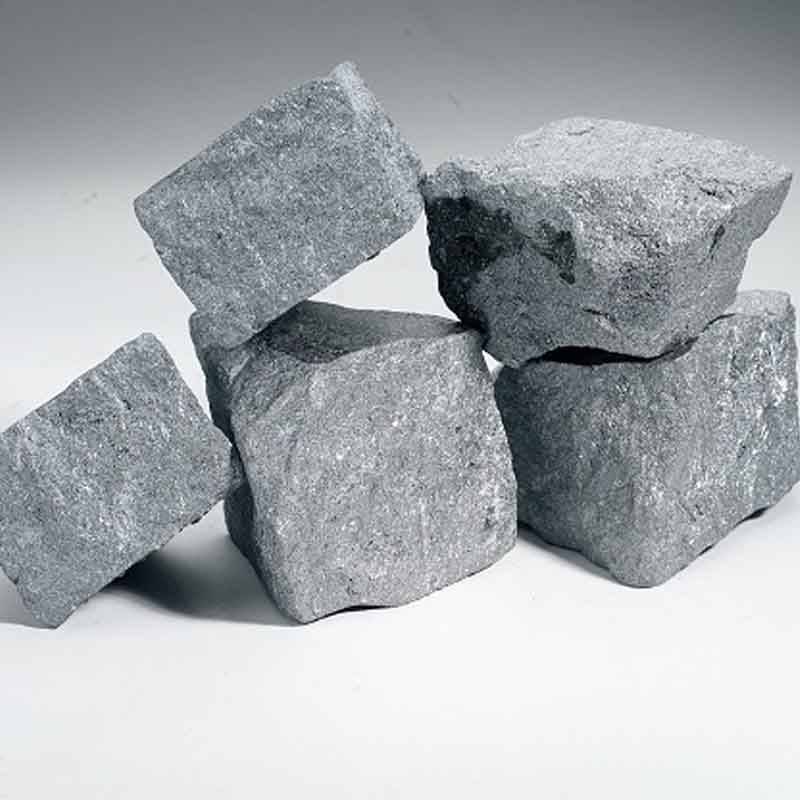

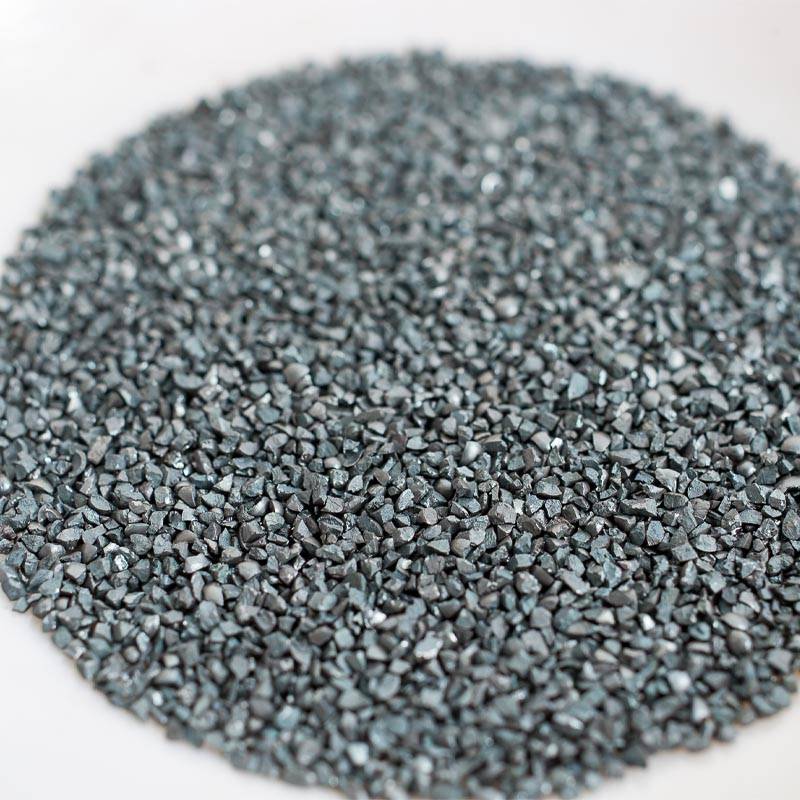

Model/Size: 0.2-0.7mm, 1-3mm, 3-10mm

Product Detail:

Ferro silicon barium inoculant is a kind of FeSi-based alloy containing certain amount of barium and calcium, it can remarkably reduce the chill phenomenon, generating very little residue. Therefore, Ferro silicon barium inoculant is more effective than the inoculant that only contain calcium, in addition, it has same inoculating performance that the inoculant with higher content of barium and calcium would have. The combination of barium and calcium has better control on the chill than the inoculant containing calcium only has.

Key Specifications :

(Fe-Si-Ba)

|

FeSiBa |

Specification(%、≤、≥) |

|||||||||||||

|

Ba |

Si≥ |

Ca |

Al |

Fe |

B |

S≤ |

P≤ |

C≤ |

Ti |

Mn |

Cu |

Ni |

Cr |

|

|

FeSiBa2-3 |

2.0-3.0 |

75 |

1.0-2.0 |

1.0-1.5 |

0.05 |

0.04 |

0.5 |

|||||||

|

FeSiBa4-6 |

4.0-6.0 |

70 |

1.5-2.0 |

1.5-2.0 |

0.05 |

0.04 |

0.5 |

|||||||

|

FeSiBa4-6 |

4.0-6.0 |

70 |

1.5-2.0 |

≤1.5 |

0.05 |

0.04 |

0.5 |

|||||||

|

FeSiBa10-12 |

10.0-12.0 |

62-69 |

0.8-2.0 |

1-1.8 |

0.03 |

0.04 |

0.5 |

|||||||

|

FeSiBa20-25 |

20.0-25 |

55 |

≤2.0 |

≤2.0 |

0.03 |

0.04 |

0.5 |

|||||||

|

FeSiBa25 |

25.0-30 |

53 |

≤2.0 |

≤2.0 |

0.3 |

0.04 |

0.5 |

|||||||

|

FeSiBa30 |

30.0-35 |

50 |

≤2.0 |

≤2.0 |

0.3 |

0.04 |

0.5 |

0.4 |

||||||

|

FeSiBa35 |

35.0-40 |

48 |

≤3.0 |

≤1.5 |

0.04 |

0.04 |

1.0 |

|

||||||

Performance and features:

1. Significantly increasing graphitization core, refine graphite, promote the A-type graphite in grey iron and graphite tending to be round in ductile iron, improve spheroidizing level;

2. Immensely reduce the chilling tendency, reduce relative hardness, improving cutting performance;

3. Strong recession-resistant capability, prevent inoculation and nodulizing recession;

4. Improve the homogeneity of fracture surface, reduce shrinking tendency;

5. Stable chemical composition, homogeneous particle size, deviation in composition and quality deviation is low; 6.Low melting point (near 1300℃), easy to be melt in inoculation processing, little scum.

Application :

1. Ferro silicon barium alloy is mainly used for deoxidization and desulfurization in ductile iron casting industry .

2. It can also be used as additives in the production of ferroalloy.

Product detail pictures:

Related Product Guide:

To continually enhance the management technique by virtue of your rule of "sincerely, great faith and high-quality are the base of company development", we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for factory low price FeMo70 - Barium-Silicon(BaSi) – Feng Erda , The product will supply to all over the world, such as: Honduras, Panama, Sao Paulo, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products and solutions have been exported to more than 15 countries in the world and have been widely used by customers.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.