Competitive Price for Ferro Molybdenum Manufacturing Process - FerroSilicon – Feng Erda

Competitive Price for Ferro Molybdenum Manufacturing Process - FerroSilicon – Feng Erda Detail:

Size:1-100mm

Basic Info:

| Ferrosilicon International Brand(GB2272-2009) | ||||||||

|

Brand name |

chemical composition |

|||||||

|

Si |

Al |

Ca |

Mn |

Cr |

P |

S |

C |

|

|

Range |

≤ |

|||||||

|

FeSi90Al1.5 |

87.0—95.0 |

1.5 |

1.5 |

0.4 |

0.2 |

0.04 |

0.02 |

0.2 |

|

FeSi90Al3.0 |

87.0—95.0 |

3.0 |

1.5 |

0.4 |

0.2 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al0.5-A |

74.0—80.0 |

0.5 |

1.0 |

0.4 |

0.5 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al0.5-B |

72.0—80.0 |

0.5 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al1.0-A |

74.0—80.0 |

1.0 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al1.0-B |

72.0—80.0 |

1.0 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al1.5-A |

74.0—80.0 |

1.5 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al1.5-B |

72.0—80.0 |

1.5 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al2.0-A |

74.0—80.0 |

2.0 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al2.0-B |

72.0—80.0 |

2.0 |

— |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75-A |

74.0—80.0 |

— |

— |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75-B |

72.0—80.0 |

— |

— |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi65 |

65.0—72.0 |

— |

— |

0.6 |

0.5 |

0.04 |

0.02 |

— |

|

FeSi45 |

40.0—47.0 |

— |

— |

0.7 |

0.5 |

0.04 |

0.02 |

— |

Ferrosilicon is a kind of ferroalloy that is composed produced by reduction of silica or sand with coke in the presence of iron. Typical sources of iron are scrap iron or millscale. Ferrosilicons with silicon content up to about 15% are made in blast furnaces lined with acid fire bricks. Ferrosilicons with higher silicon content are made in electric arc furnaces. The usual formulations on the market are ferrosilicons with 60-75%silicon. The remainder is iron, with about 2% consisting of other elements like aluminium and calcium. An overabundance of silica is used to prevent formation of silicon carbide.

Application:

①As deoxidizer and alloy agent in steelmaking industry

②As inoculant and spheroidizing agent in cast iron

③As reducing agent in ferroalloy production

④As displacing agent in the smelting of magnesium

⑤In other applocation fields,milled or atomizing silicon iron powder can be used as suspended phase.

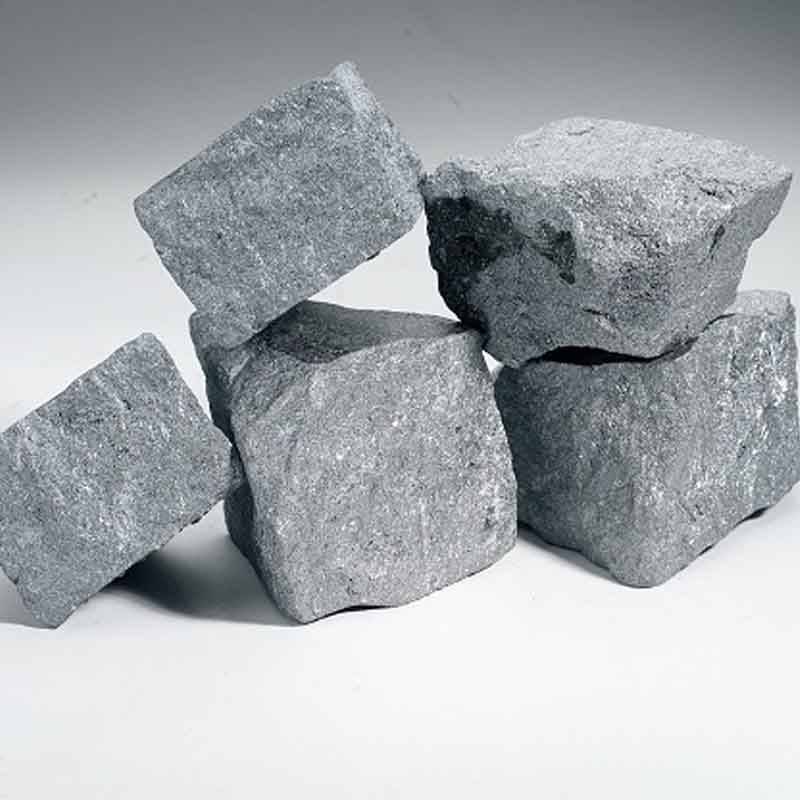

Product detail pictures:

Related Product Guide:

Using a full scientific good quality administration system, very good quality and superior faith, we win good standing and occupied this discipline for Competitive Price for Ferro Molybdenum Manufacturing Process - FerroSilicon – Feng Erda , The product will supply to all over the world, such as: Miami, Uzbekistan, Istanbul, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.