Competitive Price for Ferro Molybdenum Manufacturing Process - Carburizers(Carbon raisers) – Feng Erda

Competitive Price for Ferro Molybdenum Manufacturing Process - Carburizers(Carbon raisers) – Feng Erda Detail:

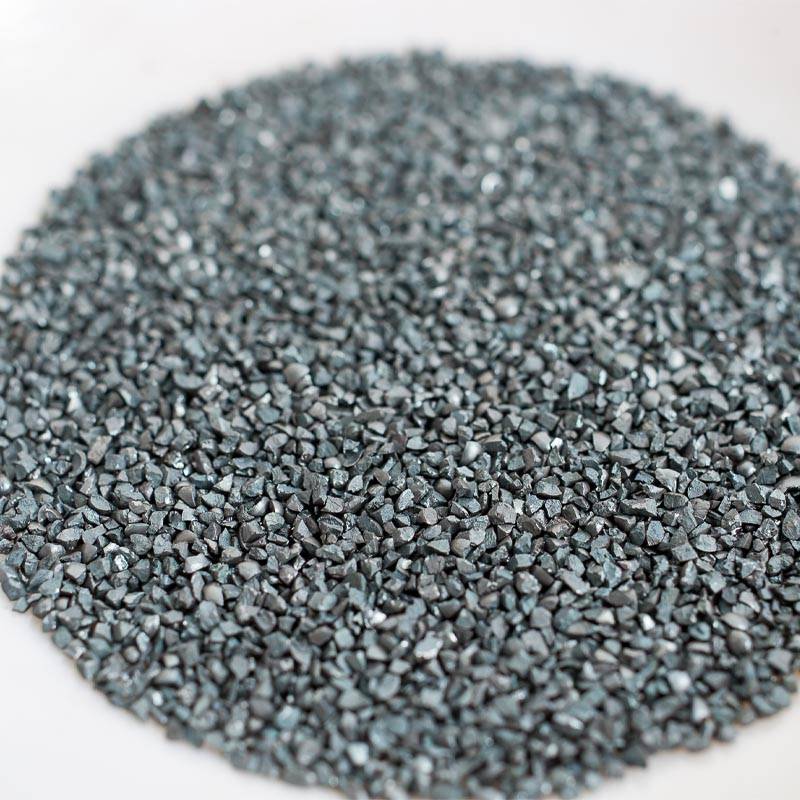

Product name: Carburizers /Carbon raisers

Model/Size: 1-5mm

Product Detail:

Carburizer, also known as carburizing agent or carburant, is a additive in steelmaking or casting to increase the carbon content. Carburizers are used for refining steel Carburizers and cast iron Carburizers, as well as other additives to Carburizers, such as brake pad additives, as friction materials. The Carburizer belongs to the additional steelmaking and ironmaking carbon-increasing raw materials. High quality carbonizers are essential additives for the production of high quality steel.The calcined petroleum coke recarburizer is produced at a temperature of about 1500 ° C in a forging smelting furnace, and the carbon content is about 98.5%.

Used as a carbon refining agent in the metallurgical industry.

According to the different raw material and manufacturing technique,the carbon raiser is divide into:carbon raiser for graphite,calcined petroleum coke,coke and anthracite.

Applications:

1.Steel Foundry,mainly used in steelmaking in electrical stove, screening water,

2.Also for shipbuilding sandblast to remove rust,producing carbon materials.

3.Reduce the cost of steelmaking effectively by replacing the traditional carburant.

4.Can improve the Carbon content in steel-melting and Ductile iron foundry.

5.Metallurgy,casting for glass production/graphite crucible/ anodes for the aluminium, titanium smelting industry

6.Others:glass sheet/pencil lead/clay bricks/conductive coating

Key Specifications :

| C | S | moisture | ash | volitale |

| min 98 | max 0,05 | max 0,2 | max 1,5 |

max 0,2 |

| Grade | Dimensions, mm* | Application |

| GL-10 | 0 – 10,0 | Added in induction furnaces |

| GL-05 | 0 – 5,0 | Quicker dissolve of carbon |

| GL-01 | 0 – 1,0 | Injection in the ladle |

Note:1,Contents could be adjusted according to customers’s specific requirement.

2,Dimensions size could be screened according to customers’ requirement.

3,Usual package is waterproof ton bag or small 25kg bag,or according to customers’ requirement.

Advantages :

The grapholite reduces:

- consumption of a carbon raiser

- energy consumption

- modifiers consumption

- furnace wearing

- the risk of slag inclusions

- heat duration

- whitening of iron castings

Product detail pictures:

Related Product Guide:

We insist about the theory of growth of 'High excellent, Performance, Sincerity and Down-to-earth working approach' to offer you with great company of processing for Competitive Price for Ferro Molybdenum Manufacturing Process - Carburizers(Carbon raisers) – Feng Erda , The product will supply to all over the world, such as: Eindhoven, Thailand, Pretoria, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We've been able to also provide you with no cost samples to meet your needs. Best efforts are going to be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you'll be able to come to our factory to find out it. We'll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we'll share the top trading practical experience with all our merchants.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.