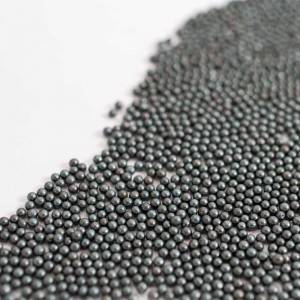

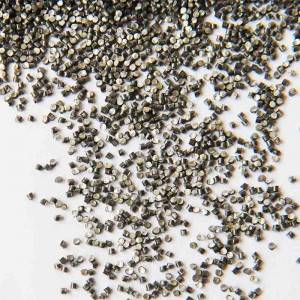

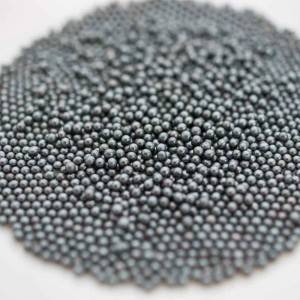

Yakakwira Carbon Yakatenderedzwa Simbi Shot

Muenzaniso/Saizi:S110-S930/Φ0.3mm-2.8mm

Product Detail:

High carbon steel shot, yakagadzirwa nesimbi yakakosha, yakaomarara uye yakapfava, ine zviri mucarbon inopfuura 0.85%. kuburikidza neatomization process, spherical particles akaumbwa nesimbi yakanyungudutswa. decarbonization, tembiricha mukudzima maitiro, pamwe nekubviswa kwepores uye kusaenzana mushure mekugadzira, izvo zvinovandudza chigadzirwa kune imwe nhanho.

Madiro Akakosha:

| PROJECT | KUTAURA | TEST NZIRA | |||

| CHEMICAL COMPOSITION |

| 0.8-1.2% | P | ≤0.05% | ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

| Si | ≥0.4% | Cr | / | ||

| Mn | 0.35-1.2% | Mo | / | ||

| S | ≤0.05% | Ni | / | ||

| MICROTRUCTURE | Homogeneous Martensite kana Bainite | GB/T 19816.5-2005 | |||

| Density | ≥7.0*10³kg/m³(7.0kg/dm³) | GB/T 19816.4-2005 | |||

| EXTERNALFORM | Mhepo gomba <10%.Conjoins.Kona yakapinza.Deformity Rate < 10% | Visual | |||

| HARDNESS | HV:390-530(HRC39.8-51.1) | GB/T 19816.3-2005 | |||

Matanho ekugadzirisa:

Zvakanakira:

Yakakwira Carbon Rounded Steel Shot ichishandisa nzira yechinyakare yekugadzira, inoshandiswa kuchenesa nekupfutidza peen kunyanya.Marapirwo ekupisa anodzorwa zvakakwana anoipa kusimba kwakanyanya uye kuramba kuneta.

uye kupedza simbi zvikamu zvinoda kuwedzera kupfeka uye kuneta zvinhu.Mukuita izvi, pfuti inobhomba chikamu chesimbi, ichigadzira madiki madiki pamusoro.

Madimples anokonzeresa kudzvanyirira pamusoro pechikamu, zvichiwedzera kuramba kwesimbi kune makatsemuka, kuneta, uye ngura.Shot peening inoshandiswa kune yakakosha, yakakwirira-kupfeka zvinhu senge magiya, shafts uye matehwe esimbi kune epamberi aerodynamic zvigadzirwa.

Applications:

Yedu yakakwira kabhoni simbi pfuti inoshandiswa mumhando dzakasiyana siyana senge;desanding, descaling, kuchenesa, kupfura peening etc.

Surface blast yekuchenesa mafogi, zvimedu zvinopisa, pombi dzesimbi, zvikamu uye zvimiro zvesimbi, kurapwa kwepamusoro pamberi pekupenda, kupfurwa kupenya kwezvidimbu zvebasa.

Surface blast kuchenesa kwesimbi isina tsvina, mahwendefa esimbi matete, asiri ferrous alloys, dacromet jasi.